Damon

-

Posts

65 -

Joined

-

Last visited

Content Type

Profiles

Articles

Forums

Gallery

Posts posted by Damon

-

-

I am more interested in the build up of crud on the coolant side which I attribute to the overheating and failure of EGR coolers.

I haven't gotten to cut apart a clogged one, but I did get pics and got the stuff back out and dried it out to see what it was. It took several days to do....

Here's the cooler as removed:

And the condensed sludge:

And the sludge dried:

That's all it takes to clog one of these.

-

No clue what caused it, really. What's odd is that it didn't seem to touch the tape or convoluted tubing. This truck runs as you see here....no codes, no symptoms.

-

I had an 04 F sereis that has the harness melted by what appears to be chemical damage. I'm not at all sure why, and the customer has not yet opted to replace it. The FICM area looks the worst.

-

Some stuff you can buy, other parts are restricted items. Basically, if it's the same part as that found on the VT365, then it's OK to get from IH. Many parts are NOT the same, and despite a good IH part number, you cannot source those "ford only" parts from IH.

-

Originally Posted By: DamonOriginally Posted By: Keith BrowningIt still seems to me that there are too many variables that can affect manifold temperatures at the point of the IAT2/MAT... therefore using IAT2/MAT would not be a good choice as direct feedback for EGR valve operation.

I asked for these variables that can't be "seen" by the other existing sensors.

My statement on variables includes EGR cooler flow issues,

I think you're missing the point here, since you're referring to IAT2 fault detection. What we're referring to is the intended job of IAT2 in EGR control and whether IAT2 can play a part in detecting EGR flow. A perfect job for IAT2 would be detecting EGR cooler flow issues or lack thereof......when it's signal's validated by the other sensor signals.

Originally Posted By: Keith BrowningEGR valve position like slow response and sticking open,Slow valve response would be another good function of IAT2 when used with EGRP vs desired. Sticking open is another.....These are all variables in MAT that can be effectively "verified" by IAT2 and the other sensors.

Originally Posted By: Keith Browningclogged IAT-2 sensor,Got me there. A clogged IAT2 can't be detected and validated so well by the other sensors. That's the very heart of this thread, IMHO....What happens then?

Originally Posted By: Keith Browningcooling system concerns, sticking turbocharger vanes and charge air cooler concerns. OF COURSE there ARE ways of "cross checking" what the IAT-2 sensor is seeing however I think doing so would place an unnecessary load on the processor.If the role of the processor is to analyse inputs, why is this an unnecessary load? It's all part of the job. It's actually "harder" to ignore.

Originally Posted By: Keith BrowningHow many ways to you think the PCM is going to cross check this sensor when it uses the EGRP sensor to control the EGR valve?Maybe you misunderstood me. I'm saying the PCM is using IAT2 to cross check the EGRP, not the other way around. To command EGR and see EGRP is fine, well and good, but if the desire is to determine flow, EGRP isn't enough. It needs to see EGRP and IAT2 rise (as well as the other sensors to validate the speed density calculations to comoute EGR flow)to determine if the flow is as was intended.

Originally Posted By: Keith BrowningThis is described as a closed loop function which tells us this is the direct feedback for EGR valve operation.Valve operation, yes. SYSTEM operation, no. The sensor can only report th eposition of the valve. It's described also as a delta pressure feedback system elsewhere. You can't do this without IAT2, plain and simple.

Originally Posted By: Keith BrowningIn reading the OBD theory and operation information the only time I see IAT2, or MAT, mentioned is EGR system and comprehensive component monitors in checking efficiency of the cooler. This has NOTHING to do with closed loop operation. More reading discovered that fault detection only occurs during the following conditions as quoted from the PCED:Quote:Fault DetectionThe low idle engine speed is between 600 and 750 RPM . The exhaust gas recirculation ( EGR ) valve position is greater than 0.08 volt. The mass fuel desired ( MFDES ) is between 4 and 16 mg/stk, at low idle for a minimum of 30 seconds. No exhaust pressure (EP), barometric pressure ( BAP ), manifold absolute pressure ( MAP ), pressure signal, intake air temperature ( IAT ), IAT2 temperature signal, vistronic drive fan ( VDF ) fan P0480, or EGR related faults.

Fault condition: IAT2 exceeds a calibrated temperature for more than 30 seconds, based on IAT temperature.

DTC Description

P2457 = Exhaust Gas Recirculation ( EGR) Cooler System Performance

Nothing I said disagrees with that quote. What could we expect if the sensor were fouled? IAT2 would NOT rise above the threshold, and NOT fail the monitor. So then, under those conditions with a clogged IAT2 incapable of quickly seeing a temp rise, could EGR flow be excessive and not log any faults?

Yes, it can.

-

I actually had an experience with a non responsive iat2 sensor causing a severe over active egr valve last week. Smoked (black) on tip in consistantly when warmed up, egr cmnd shot to 100% an every tip in. Pissed around for a few hours, and noticed if i took command of egr @ 0%, concern was gone. Also found that @ 100% egr command, egr vp @4.5v, driving under load, iat2 was only 10`c warmer than iat 1. Cleaned iat 2 sensor and concern was 100% fixed. This was on a 2006 with 85000 kms.

Kinda what I was expecting. Thanks!

-

Quote:Name some variables that can't be cross-checked and validated by the other sensors.

Well, if your only asking about IAT2 variables-

No you missed the question. Keith said:

Originally Posted By: Keith BrowningIt still seems to me that there are too many variables that can affect manifold temperatures at the point of the IAT2/MAT... therefore using IAT2/MAT would not be a good choice as direct feedback for EGR valve operation.I asked for these variables that can't be "seen" by the other existing sensors.

-

It still seems to me that there are too many variables that can affect manifold temperatures at the point of the IAT2/MAT... therefore using IAT2/MAT would not be a good choice as direct feedback for EGR valve operation.

Name some variables that can't be cross-checked and validated by the other sensors.

-

* Total Side Note *

Remember that topic on that aftermarket EGR cooler? In my research I learned that there is a correlation between NOx and opacity...

Of course it does. J1667 makes that kinda obvious. Why else would we be using opacity to emissions test vehicles that weren't really certified to an opacity standard?

Do you think that the aftermarket cooler somehow alters emissions levels? To me it looked like an 03 style cooler for the 04-newer style engines.

It is fun to try to think about the results we might expect if we cooled EGR too much or too little, however....

-

But we are straying fat, far away from how IAT2 is actually used... and getting a straight answer twice in a row doesn't seem to happen.

To reduce those temps MORE EGR would be commanded rather than less....

I think we're in agreement here, but it's hard to glean from your words.

The OBDII operation summary makes clear (to me) that the EGR system is monitored and operated in part by comparing MAP to the speed density calculation. That makes IAT2 a big player, since it's very important to speed density calculations. I agree that the necessary variables can be inferred from the sensors already present. The lack of direct reading makes these existing sensors really important.

And I think that the gooped IAT2 will add EGR, which I think is what you were alluding to.

-

I think the IC4 is available direct

-

Not to mention, water and electricity don't mix.

The low coolant probe on the older IH's had this issue too. The probe needed too much current to work, and the result was corrosion on the tip of the sensor. The TSI was to install a module to take the load off the sensor. It's really just a small solid state relay.

-

I can't reach the same conclusion. The same operation summary says:

Quote:The Delta Pressure Exhaust Gas Recirculation (EGR) System is a closed loop EGR Valve Position control system. It utilizes an exhaust manifold pressure sensor, an intake manifold pressure sensor and a speed density estimate of total mass flow and derives a desired EGR Valve position based on a desired EGR flow percentageCan this speed density estimate be accurate without knowing the temperature of this air? IAT alone can't do that.

Quote:The EGR Monitor is a series of electrical tests and functional tests that monitor various aspects of EGR system operation.When normal EGR rates are being commanded and when the engine enters into either one of two specified operating ranges, a flow check is performed. The operating ranges are defined to insure an adequate amount of EGR is being requested to allow for an accurate estimate of the EGR flow percentage. At this point EGR flow is estimated based on the difference between the Mass Air Flow (MAF) sensor reading and the total mass flow calculated by the speed density calculation. The estimated EGR flow is then compared to the expected EGR flow to determine if there is insufficient or excessive flow.

Even for a P0401 or P0402 monitor to run, the following sensors must be OK:

Intake Air temperature Sensor 2 (IAT2).

Mass Air Flow Sensor (MAF)

Barometric Pressure Sensor (BARO)

Intake Air Temperature Sensor (IAT)

Engine Oil Temperature Sensor (EOT)

Manifold Air Pressure Sensor (MAP)

Exhaust Pressure Sensor (EP)

Exhaust Gas Recirculation Position Sensor (EGRP)

Exhaust Gas Recirculation Valve Actuator Monitor (EGRAM)

Electronic Variable Response Turbocharger Actuator (EVRT)

-

So then why would you believe that IAT2 would be used instead of IAT for disabling EGR in extreme temps on a 6.0? I mean if IAT2 was frigid cold, it couldn't possibly have any EGR to disable. if it was too hot, it probably couldn't disable it anyway.

-

The 6.4 has an EGRT inlet and outlet sensor, so the function of IAT2 wouldn't be needed for any part of EGR control until something went wrong elsewhere.

-

Let's not forget some of the other conditions that can influence IAT2.... restricted airflow across the CAC is the first one that comes to mind. We have seen cooling stacks about plugged right off - and the first drivability complaint we generally hear of is engine overheat... If IAT2 was consistantly higher than some predetermined level, would we expect to see an excess EGR flow code?

No, because it still has pintle position and EBP to look at...

Originally Posted By: Jim WarmanHigh boost levels would also deliver higher than normal IAT2... stationary PTO operation or a V-Mac compressor - used to be an operator would open the hood on his truck when running an engine driven air compressor but that practice appears to have gone by the wayside.Not higher than normal in this case either.... because the sensors are accurately reporting information that coincides with the actual conditions. I have a customer that runs a splitshaft PTO off a few 550 6.0's at WOT full load and not moving. That's not common these days, but still done. Where problems usually occur is when sensors report information incorrectly, or correct information too late for correction.

Originally Posted By: Jim WarmanI can see IAT2 being (in current configuration and because each reflash needs to, as far as I see it, pass EPA scrutiny for specific criteria) used in computations for fuel, boost and EGR decisions, but only in the sense that high charge air temp will deliver high combustion chamber temps.Navistar engines (those designated as VT365) and "Ford" engines (those designated 6.0PSD) are worlds apart in so many respects.... 90some HP being something that sticks out like a wedding prick. There be a chance that comparing the two operating systems might be akin to comparing road kill to fresh veggies... I DON'T KNOW.... and the few times I have asked, I have usually gotten a reply that was almost, nearly in the ballpark of the answer I wanted/expected....

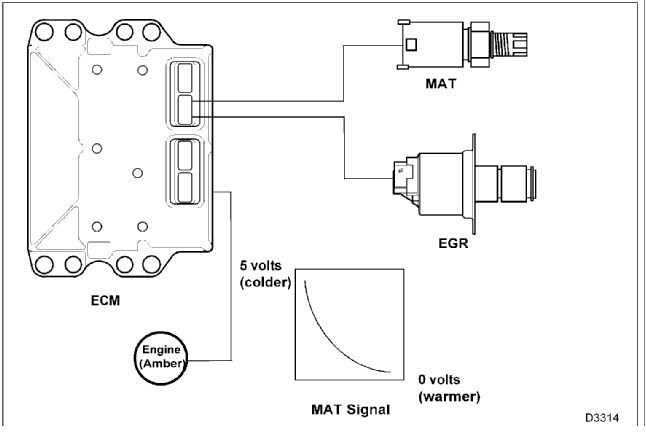

No doubt. I was NOT trying to imply that the engines are identical in their operation, but it appears that IH and Ford are using the same technical information source when discussing the theory of operation of these engines. All the (Ford AND IH) theory of operation books I see that show a circuit function diagram of the IAT2, they always show it with the EGR in the schematic as well, like the picture I posted earlier does. There's a good reason for that.

Originally Posted By: Jim WarmanSo... what can we be sure of when we discuss IAT and IAT2? IAT before we take our intake air and "process" it. If the truck has a stock air filter, IAT will be close to ambient.... If the truck has a cold air intake, expect something much higher.... closer to underhood temps. IAT2 is what we get AFTER we process (or perhaps MISprocess) our intake air. Far too many variables begin to creep into the picture - have they been accounted for? Do they need accounting for?Yes, they do. Boost, CAC effect, EGR, RPM, and coolant temp will all play a role in the deviation of IAT2 vs IAT. I'll agree that this sensor isn't a MAJOR input, but it is part of the sensor redundancy needed to validate some inputs when others might disagree.

Originally Posted By: Jim WarmanBut, somewhere along the line, we come to the realization that a gooped off IAT2 is the sign of quite another concern.... perhaps, instead of analysing the effects of a gooped IAT2.... we should get IAT2 to stop getting gooped????Honestly, I think it's a location thing. That should be an easy fix. The irony of this is that the goop on the IAT2 causes more goop on the IAT2, which is kinda what I was trying to get at when everybody giggled at the dealer that sold the IAT2 on a truck that clearly needs more work. While it won't fix the truck that started this thread, it would be an important part of the work needed to prevent the repeat occurrance, IMHO.

-

I was always under the impression that the two sensors also gave the PCM a good indication how well the intercooler was doing/how hot the charge air temp was.

Yep, it does that too. But oddly, you don't see these sensors on many aftercooled engines that don't also have EGR valves. So it stands to reason the primary function of this sensor is for emissions control feedback. Remember: We don't have anything in the exhaust system, this all needs to be inferred.

-

Originally Posted By: DamonI can't say that based on this alone it stands to reason that IAT2 isn't partly responsible for fault detection though.

It would be great to hear more on this from an engineer that actually has the answer. It seems the more I go looking for answers the more questions I have.

I had one additional thought for us to chew on. I have yet to see an IAT2 sensor that didn't have carbon packed around the thermistor and I question the impact of that carbon on the sensor's ability to react to temperature changes quickly or it's accuracy for that matter.

Precisely my point. I can't say I've seen a skewed or failed IAT2, but we've all seen heavily insulated (and therefore lazy)ones. THAT just

*MAY*

*MAY* cause a bit more EGR than we'd have otherwise.

cause a bit more EGR than we'd have otherwise. -

Originally Posted By: Damon

I have no opinion, because I haven't tested it. It wouldn't be hard to do, and I assure you I will do so. I'll see how EGR operates when IAT2 matches IAT as an ambient temp sensor under identical driving conditions.

I'm not following you here. Are you stating you are going to watch EGR command when IAT and IAT2 are the same temp? They almost never are, except at cold startup when the EGR won't be functioning because cold engines don't produce NOx (which is what an EGR is there to reduce). During driving conditions, IAT and IAT2 will never match.

Or, are you stating you will modify the IAT2 signal via an external sensor or signal generator, to match the IAT's signal?

Correct. Simply plug another IAT2 sensor into the harness, but leave it out of the intake. That'll be an easy way to make another ambient temp sensor and it'll be fun to see how EGR behaves as a result.

Originally Posted By: Bruce AmackerI've always felt the PCM was watching IAT2 to confirm EGR flow, as well as using it as a general input for fuel strategy, timing, idle speed, glow plug, and VGT, among other things..

Exactly my understanding as well.

-

Cool! It has been a while since we have had a spirited technical discussion.

Well, cool. I do NOT profess to be a guru at 6.0's but anyone that knows me knows I'm rather famous for spirited technical discussion. Most of the time I haven't got a fucking clue what I'm talking about. This is another one of those times.

Originally Posted By: Keith BrowningOnly the OBD System Operation manual mentions EGR in relation to IAT2 - cooler efficiency to be exact. There are other monitors and sensor checks requiring a valid IAT2 signal however.Which adds at least something important to this discussion. IAT2 IS or MAY BE at least responsible for managing some part of EGR operation.

Originally Posted By: Keith BrowningMY OPINION is that IAT2 has no direct role in EGR operation, control or (feedback relative to control.) You have an EGR position sensor providing direct EGR valve position feedback and the EBP, MAF and MAP sensors are used to calculate the EGR flow rate and for concern detection.I have no opinion, because I haven't tested it. It wouldn't be hard to do, and I assure you I will do so. I'll see how EGR operates when IAT2 matches IAT as an ambient temp sensor under identical driving conditions.

Right now, all I have is IH saying it's important and Ford (belatedly admitting) it might play a role in EGR operation and fault detection.

All the books I have show the same pictures when sdiscussing the sensor. They ALL seem to show IAT2 with EGR in the theory sections.....

Then IH comes out and says things like this:

Originally Posted By: IH service infoThe ECM calculates the appropriate desired EGR valve position in response to the changing engine speed, fuel desired, operator demand, engine operating temperatures, exhaust back pressure, boost pressure and altitude. Components involved with the control of the EGR include the following:

Barometric Absolute Pressure (BAP) sensor

Exhaust Back Pressure (EBP) sensor

Manifold Air Temperature (MAT) sensor

Manifold Air Pressure (MAP) sensor

Accelerator Pedal Position Sensor (APS)

Engine Coolant Temperature (ECT) sensor

Engine Oil Temperature (EOT) sensor

Electronic Variable Response Turbocharger (EVRT™) actuator

The EGR actuator consists of two components, a valve with actuator (solenoid) and a position sensor to monitor valve movement. The EGR is at the front of the engine on top of the intake manifold.

The EGR actuator is a variable position valve that controls the amount of exhaust that enters the intake system. The EGR valve is controlled by the ECM using a pulse width modulated signal. The system is closed loop using the EGRP as input. Other inputs that are used to calculate the desired position of the EGR valve include BAP, EBP, MAT, VGT control, MAP, APS, and EOT.

IH isn't Ford, nor are they infallible in their service info either. But it appears that IH is clearer in their remarks about the role of IAT2 in the operation of the EGR valve.

Originally Posted By: Keith BrowningMY EXPERIENCE has been that I have never had a concern with the IAT2 or and EGR concern where diagnostic tests so much as mention IAT2. As mentioned, I have been taught that using IAT2 data can help identify an EGR efficiency concern using data logger. In fact, I have diagnosed a few CLOGGED EGR cooler/ports that had no DTC's in memory and only one failed the IDS-EGR test because it was totally blocked. The others kept spitting pebble-sized pieces of carbon into the valve hanging them up.I am willing to learn more...

My experience matches yours here. We can agree on this. I can't say that based on this alone it stands to reason that IAT2 isn't partly responsible for fault detection though.

-

Thanks for at least a partial vindication. I see all Ford's references to this sensor as being used to measure manifold air temp but it falls short of saying what for. IH makes no mistakes about it though.

It still won't cause an EGR cooler to fail, but it is an integral part of the EGR system, IMHO.

-

To quote the coffee table book, "The IAT1 sensor's primary function is to measure intake air temperature to control the timing and fuel rate when cold starting.Originally Posted By: DamonOriginally Posted By: Keith BrowningAccording to the PCED the PCM uses the IAT-2 signal to control timing and fuel rate during cold starts and to provide an input to the cold idle kicker. I recall asking an engineer about this sensor back when we took note that these sensors coke up who confirmed this information.

So what's the other IAT used for then?

Which contradicts Keith's comments (he said this is the job of the IAT2 sensor, see quote above) and also directly contrdicts at least ONE other coffee table book that states that the IAT sensor in the MAF is used ONLY for fan operation and AC operation (see the 2004 coffee table book page 29)

Originally Posted By: BrunoWilimek"The primary function of the IAT2 sensor is to provide a feedback signal to the PCM indicating manifold air temperature."It stands to reason it's part of the rationality check for setting EGR flow codes instead of sensor position codes.

-

According to the PCED the PCM uses the IAT-2 signal to control timing and fuel rate during cold starts and to provide an input to the cold idle kicker. I recall asking an engineer about this sensor back when we took note that these sensors coke up who confirmed this information.

So what's the other IAT used for then?

I couldn't get accurate info through Ford about the theory behind the IAT2 sensor, but on the IH VT365, they call it the MAT (same sensor and location) and the IAT is the one in the MAF. So, IH says about the MAT:

Originally Posted By: "IH VT365 service info"Manifold Air Temperature (MAT)The MAT sensor detects intake manifold air temperature.

The MAT signal is monitored by the ECM for EGR operation.

The MAT sensor is installed in the right front of the intake manifold.

-

For the purpose of the discussion.....

I understand the IAT2 sensor is used (in part) to detect EGR flow. Is this incorrect? If so, would it NOT stand to reason that a fouled IAT2 sensor might cause overactive EGR due to the slow response of the sensor due to the carbon buildup?

Forgetting the BS of boiling coolant due to IAT2, there's at least the appearance of some merit to the theory that a lazy IAT2 might cause the EGR to be open longer than would be otherwise, thereby increasing the need for greater heat exchange in the cooler. That, combined with a clogged oil cooler, could cause the EGR cooler to fail.

'01 F-350 Stalls but restarts

in 7.3L Power Stroke® Diesel Engines

Posted

An ICP related issue like aeration or cavitation would cause a hard restart, extended crank and rough run both before the stall and after restart. I'm with Aaron here, I think the screens in the sending unit module are clogged. We see a LOT of these nowadays.

That's not the "sock" since it uses a suction strainer screen and there are 2 tubular screeds inside the sender module itself. Unknown to many, there's also an integral (and NOT replaceable) fine mesh screen on the rail mounted fuel pump inlet too.